The post Soil Properties and Laboratory Tests appeared first on CONSTRUIRE.

]]>| Properties | Tests |

|---|---|

|

Particle size

|

Sieve and Hydrometer Analysis

|

|

Consistency Limits

|

Liquid, Plastic, and Shrinkage Limit

|

|

Capacity to absorb and hold moisture

|

Capillary and Permeability Tests

|

|

Cohesion and internal friction

|

Triaxial, Direct Shear, and Bearing tests

|

|

Density

|

Field Density

|

|

Settlement Under load

|

Consolidation test

|

|

Volume change

|

Swell and Shrinkage tests

|

|

Unit Weight

|

Weighing and Calculation of Specific Gravity

|

|

Strength

|

California Bearing Ration (CBR)

|

Laboratory Tests

-

Grading TestStandard sieves or screens are used in the test. The sieves are made up of wire mesh which has square openings. The coarse sieves are designated by the width of openings as 75, 63, 50, and 19-millimeter sieves. The finer sieves are designated as 4.75, 0.425, 0.200, 0.150, or 0.075 millimeter sieves. The widths of the opening which correspond to the sieves commonly used in soil testing are as follows:

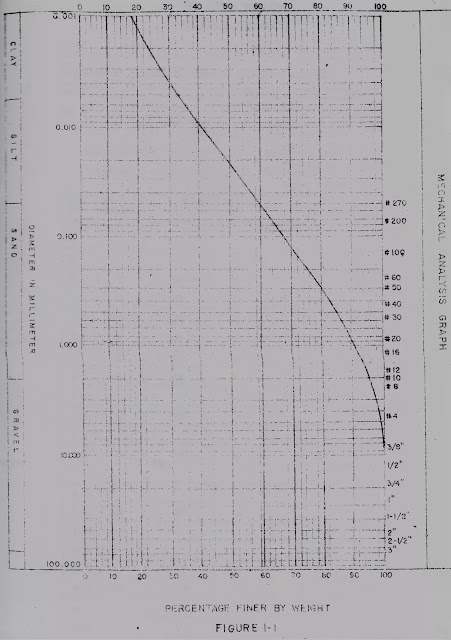

Width of Opening (Std) Alternate U.S. Standard Sieve No. 4.25 4 2.36 8 1.18 16 0.600 30 0.300 50 0.150 100 0.075 200 The 2.00 mm sieve is the dividing line between gravel and sand, and the dividing line between sand and silt is 0.05 mm. Material which passes the 0.075 mm sieve is the finest that is used in the sieve analysis, the[ proportion of silt and clay cannot be determined by the test alone.The grading or mechanical analysis has its objective the determination of the proportion of different grain sizes which are present in a soil particle which is finer than a stated sieve or diameter. Two methods of determining the grain size distribution in soil are in common use: the combined sieve analysis, with a wash test to determine the percentage passing the 0.075 mm sieve.In the first method, a representative sample of soil is selected and divided by passing it over a 2.00 mm. The portion retained is tested by the sieve analysis. A portion of the material passing the 2.00 mm sieve is dispersed and put into suspension in water. Changes in the specific gravity of the suspension with time are noted by the use of a hydrometer. The hydrometer analysis is based upon Stoke’s Law which states that the rate of settlement of a particle out from a suspension is a function of its size. Since the larger particles settle out of suspension more rapidly than do smaller particles, the time rate of settlement provides a measure of the relative size of the fine soil grains. As the particles settle, the density or specific gravity of the suspension decreases; this change is the information supplied by the hydrometer reading. The known relationship may then be employed to calculate the percentage of grains of various averages remaining in suspension or which have settled out. For each of the time intervals specified in the test procedures, there may be determined the percentage of the dispersed sample which is finer or coarser than certain grain size. The standard procedure for mechanical analysis of soils is AASHTO T88.The results of the sieve analysis and the hydrometer analysis are combined and the results are presented graphically by means of a particle size distribution curve. The curve is drawn on a semi-logarithmic graph sheet with the particle sizes plotted as abscissa on the logarithmic scale and the percentages smaller than the various sizes as ordinates on the arithmetic scale as shown in figure I-1. The meaning of this form of presentation is shown by an examination of the curve. In this particular soil, 4% is gravel since 96% is finer than a 2 mm sieve. The soil contains about 36% of sand since 60% is finer than 0.05 mm. About 34% of the material is of clay size, less than 0.005 mm. Thus, 26% of the soil is silt. The make-up of this soil then is gravel 4%, sand 36%, silt 26%, and clay 34%.For soil classification purposes as in AASHTO M45, the combined sieve and mechanical analysis is not required. The sieve analysis and the wash test will be sufficient. For detailed standard procedures, see AASHTO Test methods T-11 and T-27, over a nest of sieves, as well as that which passes the 0.075 mm frequently called “combined silt and clay”. The test report is illustrated in Appendix I-1.Significance of Grading Test

This test gives the particle size distribution of a given soil. The shape of the curve drawn will show a glance the general grading characteristics.

The gradation test is widely used in the classification and identification of soils. The classification of soils is covered in detail in AASHTO M45, see Appendix I-2.

The test results are also used in measuring permeability, notably in setting up criteria for drainage filters. It has also been shown that soil capillarity, which is the attraction of water from a water table, is related to effective diameter. The rise of water in a capillary opening is proportional to the square of an effective diameter.

The post Soil Properties and Laboratory Tests appeared first on CONSTRUIRE.

]]>The post SOILS – General Information appeared first on CONSTRUIRE.

]]>Definition:

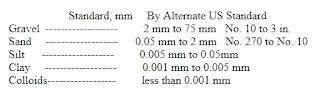

Standard, mm By Alternate US Standard

Gravel ——————- 2 mm to 75 mm No. 10 to 3 in.

Sand ——————- 0.05 mm to 2 mm No. 270 to No. 10

Silt ——————- 0.005 mm to 0.05mm

Clay ——————- 0.001 mm to 0.005 mm

Colloids—————— less than 0.001 mm

Engineering Properties

Granular Soils:

- Good load-bearing qualities.

- Permeable, hence they drain readily.

- Comparatively incompressible when subjected to static loads.

- Not subject to changes in strength or volume due to variation in water content. However, loose granular materials will undergo a considerable reduction in volume if subjected to vibratory loads.

Fine-Grained Soils:

- Poor load-sustaining qualities.

- Highly impermeable.

- Compressible under sustained load.

- Subject to changes in volume and strength due to variation in water content.

Organic Soils:

Identification – Visual and Texture

-

- GravelRounded or water-worn pebbles. No cohesion or plasticity. Crunchy underfoot.

- SandGritty and lose grains. Individual grains are readily seen and felt. No plasticity or cohesion. If dry, a cast formed in the hand will fall apart; if moist, a cast will crumble when touched.

Two simple manual tests are used to detect the presence of fines in the sand. If a handful of dry sand is sifted through the fingers and allowed to fall on the ground, it is considered dirty if an appreciable amount of dust appears. A small quantity of wet or dry sand is placed in a test tube or bottle, water is added and the bottle is shaken vigorously. The sand particles will settle 76.2 mm (3 in) in about 10 seconds. Therefore, if after about half a minute the top 76.2 mm (3 in) of water does not appear substantially clear, the sand may be considered dirty.

- Silt has fine and barely visible grains. When in a dry pulverized condition, it feels soft and floury. Can hardly be made plastic. Exhibits little or no strength when air-dried. A dried cast is easily crushed in the hands.

In the wet state, organic silt can be rolled into thin threads, but if the threads are more than a few inches long, they will not support their own weight if held by one end.

When mixed with water to the consistency of a thick paste, the surface of inorganic silt will appear wet and shiny if a pat is shaken in the palm of the hand; if the pat is squeezed, the surface will dry up, appear dry, and eventually crack. Clay, if treated similarly will not change in appearance. - Clay can be made of plastic by adjusting its water content. Cohesive. Exhibits considerable strength when dried; difficult or impossible to crush in hands.

Clay can be molded and rolled into thin threads without breaking or crumbling within a moderate to a wide range in water content, and threads of considerable length will support their own weight when held by one end. - Organic Soilsgray to black color. Fibrous structure due to the presence of undecomposed plant matter. unhealthy sewage-sludge odor. Found as deposits in swamps and peat bogs.

The post SOILS – General Information appeared first on CONSTRUIRE.

]]>