The post Asphalt in Road Pavement Free Online Reviewer 2022 appeared first on CONSTRUIRE.

]]>Importance of Asphalt to Highway Engineering

- When mixed with mineral aggregates to form the upper layers of the pavement structures holds the aggregates in position and give them resistance to displacement by traffic. It provides tensile strength to the asphalt mixture and enables the pavement to resist bending stresses due to traffic load.

- It also gives flexibility to the pavement and enables it to conform to minor irregularities of the base without failure.

- It is preferable to a cement concrete road due to its lower initial cost and more uniform riding surface.

- In more developed countries, there are more asphalt roads than cement concrete roads. In their road life studies, the average lifespan of all types of asphalt roads is twenty (20) years.

Characteristics of Asphalt

- Hydrocarbons that are soluble in carbon disulfide. At normal temperatures, they are in solid form, and when heated, they will soften and flow. When mixed with aggregates in their flaccid state, they solidify and bind the aggregates together forming a pavement surface.

- Highly waterproof and can seal the road surface against excess surface water.

- Highly cementitious. With the proper amount of bitumen at the road surface, it can bond granular particles together that will resist traffic wear and displacement.

- Bituminous road surfaces are relatively flexible and will adjust to base variations.

- When properly selected, the bitumen can maintain its ductility and bond which in return can withstand deterioration due to withering.

Sources and Nature

Bituminous materials used in road construction are from the distillation of crude oil. The distillation process can be accomplished by mechanical or natural means.

- Kinds of Bitumen

- Natural/rock asphalt – formed when crude petroleum oils work their way to the earth’s surface through cracks. Then the action of the wind and the sun drives off the lighter oils and gasses leaving behind black and plastic residue.

- Manufactured or petroleum asphalt – obtained by the distillation process from crude petroleum

- Asphalt Cement – 40-300 penetration grade

- Oxidized or Blown asphalt – 0-30 penetration grade

Classification, Chemical, and Physical Properties

Bitumen used in road construction is called asphalt cement, a highly viscous and sticky material.

- Classification and Grade

- Asphalt Cement

- Penetration grade

- Liquid Asphalt

- Cutback Asphalt – asphalt cement with solvent

- Medium Curing

- Rapid Curing

- Emulsified Asphalt – asphalt cement + water +emulsifier

- Anionic – negative charge

- Cationic – positive charge

- Cutback Asphalt – asphalt cement with solvent

- Asphalt Cement

- Chemical Properties

- It is basically composed of various hydrocarbons with traces of sulfur, oxygen, nitrogen and other elements. It is however composed of two main components such as the following.

- Asphaltene – This component gives color and hardness

- Maltene – This component is composed of resin which provides stickiness or adhesiveness and oil which influences viscosity and softness.

- Existing test for analyzing chemical composition requires sophisticated laboratory equipment and technical expertise not readily available in most laborites where such testing is done.

- It is basically composed of various hydrocarbons with traces of sulfur, oxygen, nitrogen and other elements. It is however composed of two main components such as the following.

- Physical Properties

- Consistency of asphaltic material ranges from very thin liquid to stiff semi-solid state. It is also graded by its consistency at given temperatures.

- Temperature Susceptibility – All bituminous materials are thermoplastic. This means that it becomes harder as its temperature decreases and softer it becomes when its temperature increases. It also varies among bituminous materials from different sources even if they are of the same grade. It is important to determine the temperature susceptibility of the bituminous material to be used in a paving mixture because it indicates the proper temperature when to mix the bitumen and aggregates and the proper temperature at which to compact the mixture on a roadbed.

- Adhesion and Cohesion

- Adhesion – It is the ability of the bituminous material to stick to the aggregates in a paving mixture.

- Cohesion – The bitumen’s ability to hold the aggregate particles firmly in place in the finished pavement.

- Durability – The resistance of the bitumen to change in properties due to weathering or aging which involves chemical and physical reaction called oxidation.

- Hardening – Bitumen tends to harden in the paving mixture during construction which occurs when heated to higher temperature.

- Physical Tests

- Consistency Test

- Viscosity Test – Measures the resistance to flow

- Penetration Test – Measures the distance that a standard needle will penetrate a sample at a given temperature in a specified time.

- Temperature Susceptibility Test

- Softening Point Test – It indicates the temperature at which the harder type of bitumen reaches an arbitrary degree of softening.

- Loss of Heating

- Determines the rate of loss of volatile oil of bitumen when heated and the change in penetration caused by excessive heating.

- Ductility Test

- Measures the ability of the bitumen to stretch without breaking.

- Flash Point

- Indicates safe heating temperature of bituminous materials.

- Specific Gravity

- This indicates the uniformity of bituminous product.

- Spot Test

- Determines if the bituminous material was overheated during production.

- Solubility Test

- Determines the bitumen content that is soluble in petroleum solvent.

- Distillation Test

- Determines the bituminous content of liquid asphalt.

- Sieve Test

- Determines the presence of larger globules of bituminous material in the emulsion.

- Cement Mixing Test

- Storage Stability Test

- Consistency Test

- Handling, Storage and Sampling – The inspector should be aware of the potential sources of contamination that might exist where the bituminous material is being stored and handled. It is because an inspector may be required to collect samples for testing. Inspectors must be able to identify and avoid practices that could lead to contamination of samples. Additionally, inspectors must understand the changes in volume that bituminous materials undergo when heated or cooled. It is especially important to be knowledgeable when comparing bituminous materials at quantities measured at different temperatures.

- Safe Handling of Bituminous Materials – Bituminous materials are usually heated to a temperature exceeding 149 degrees Celsius to facilitate its use. Momentary contact can severely burn exposed flesh or skin. In case of skin burns, apply cold water or ice packs to reduce the heat. Use personal protective equipment to avoid exposure to fumes coming off from hot bituminous materials such as hydrogen sulfide. Hydrogen and sulfur are naturally present in these materials.

- Storage

- Do not store in open areas exposed to rain.

- Storage areas must be clean to avoid contamination.

- Check storage drums for leakage and damage.

- Sampling

- Samples must be representative of the entire shipment.

- Contamination or other alteration of sample before testing will produce misleading test results. Misleading results obtained leads to wrong decisions such as rejection of entire shipments when it does in fact meets the specifications.

- Best practices to observe when doing sampling

- Use new and clean containers to avoid contamination.

- Seal filled containers with clean, dry and tight-fitting lids.

- Label containers clearly and properly.

Read more: CHECK HERE

Image Credit: Wikipedia

The post Asphalt in Road Pavement Free Online Reviewer 2022 appeared first on CONSTRUIRE.

]]>The post SOILS – General Information appeared first on CONSTRUIRE.

]]>Definition:

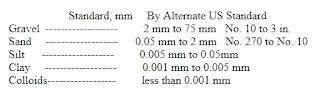

Standard, mm By Alternate US Standard

Gravel ——————- 2 mm to 75 mm No. 10 to 3 in.

Sand ——————- 0.05 mm to 2 mm No. 270 to No. 10

Silt ——————- 0.005 mm to 0.05mm

Clay ——————- 0.001 mm to 0.005 mm

Colloids—————— less than 0.001 mm

Engineering Properties

Granular Soils:

- Good load-bearing qualities.

- Permeable, hence they drain readily.

- Comparatively incompressible when subjected to static loads.

- Not subject to changes in strength or volume due to variation in water content. However, loose granular materials will undergo a considerable reduction in volume if subjected to vibratory loads.

Fine-Grained Soils:

- Poor load-sustaining qualities.

- Highly impermeable.

- Compressible under sustained load.

- Subject to changes in volume and strength due to variation in water content.

Organic Soils:

Identification – Visual and Texture

-

- GravelRounded or water-worn pebbles. No cohesion or plasticity. Crunchy underfoot.

- SandGritty and lose grains. Individual grains are readily seen and felt. No plasticity or cohesion. If dry, a cast formed in the hand will fall apart; if moist, a cast will crumble when touched.

Two simple manual tests are used to detect the presence of fines in the sand. If a handful of dry sand is sifted through the fingers and allowed to fall on the ground, it is considered dirty if an appreciable amount of dust appears. A small quantity of wet or dry sand is placed in a test tube or bottle, water is added and the bottle is shaken vigorously. The sand particles will settle 76.2 mm (3 in) in about 10 seconds. Therefore, if after about half a minute the top 76.2 mm (3 in) of water does not appear substantially clear, the sand may be considered dirty.

- Silt has fine and barely visible grains. When in a dry pulverized condition, it feels soft and floury. Can hardly be made plastic. Exhibits little or no strength when air-dried. A dried cast is easily crushed in the hands.

In the wet state, organic silt can be rolled into thin threads, but if the threads are more than a few inches long, they will not support their own weight if held by one end.

When mixed with water to the consistency of a thick paste, the surface of inorganic silt will appear wet and shiny if a pat is shaken in the palm of the hand; if the pat is squeezed, the surface will dry up, appear dry, and eventually crack. Clay, if treated similarly will not change in appearance. - Clay can be made of plastic by adjusting its water content. Cohesive. Exhibits considerable strength when dried; difficult or impossible to crush in hands.

Clay can be molded and rolled into thin threads without breaking or crumbling within a moderate to a wide range in water content, and threads of considerable length will support their own weight when held by one end. - Organic Soilsgray to black color. Fibrous structure due to the presence of undecomposed plant matter. unhealthy sewage-sludge odor. Found as deposits in swamps and peat bogs.

The post SOILS – General Information appeared first on CONSTRUIRE.

]]>